- Company

- Services

- Products

- Spare Parts

- Logistics

- Training/Classes

- Contact

- Careers

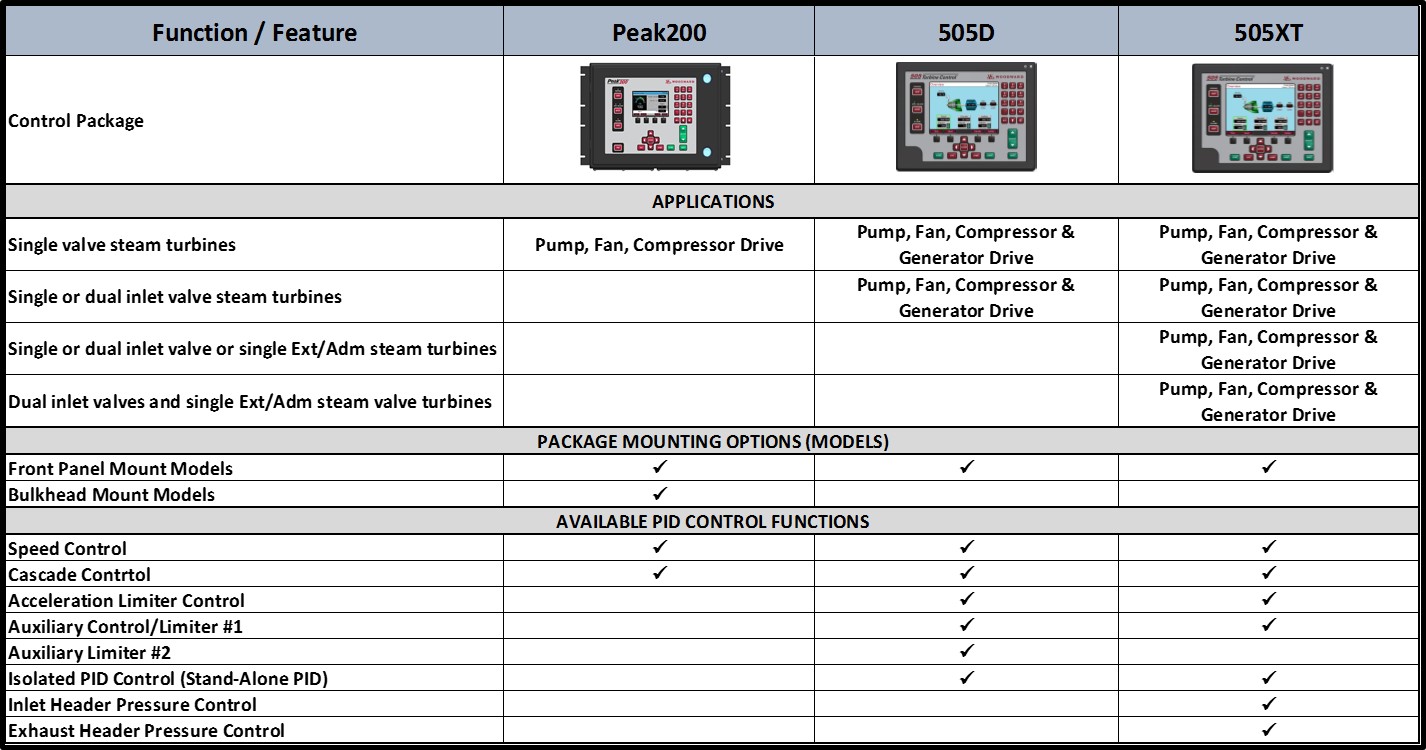

The Peak200 controller is designed to operate small single valve, or single valve rack industrial steam turbines. This cost effective steam turbine controller includes specifically designed algorithms and logic to start, stop, control, and protect small industrial steam turbines or turboexpanders driving compressors, pumps, or industrial fans.

New Design based on 505 platform

Upgrading from Peak150 to the new Peak200

The new Peak200 controllers include all the same basic functions as Peak150 controllers:

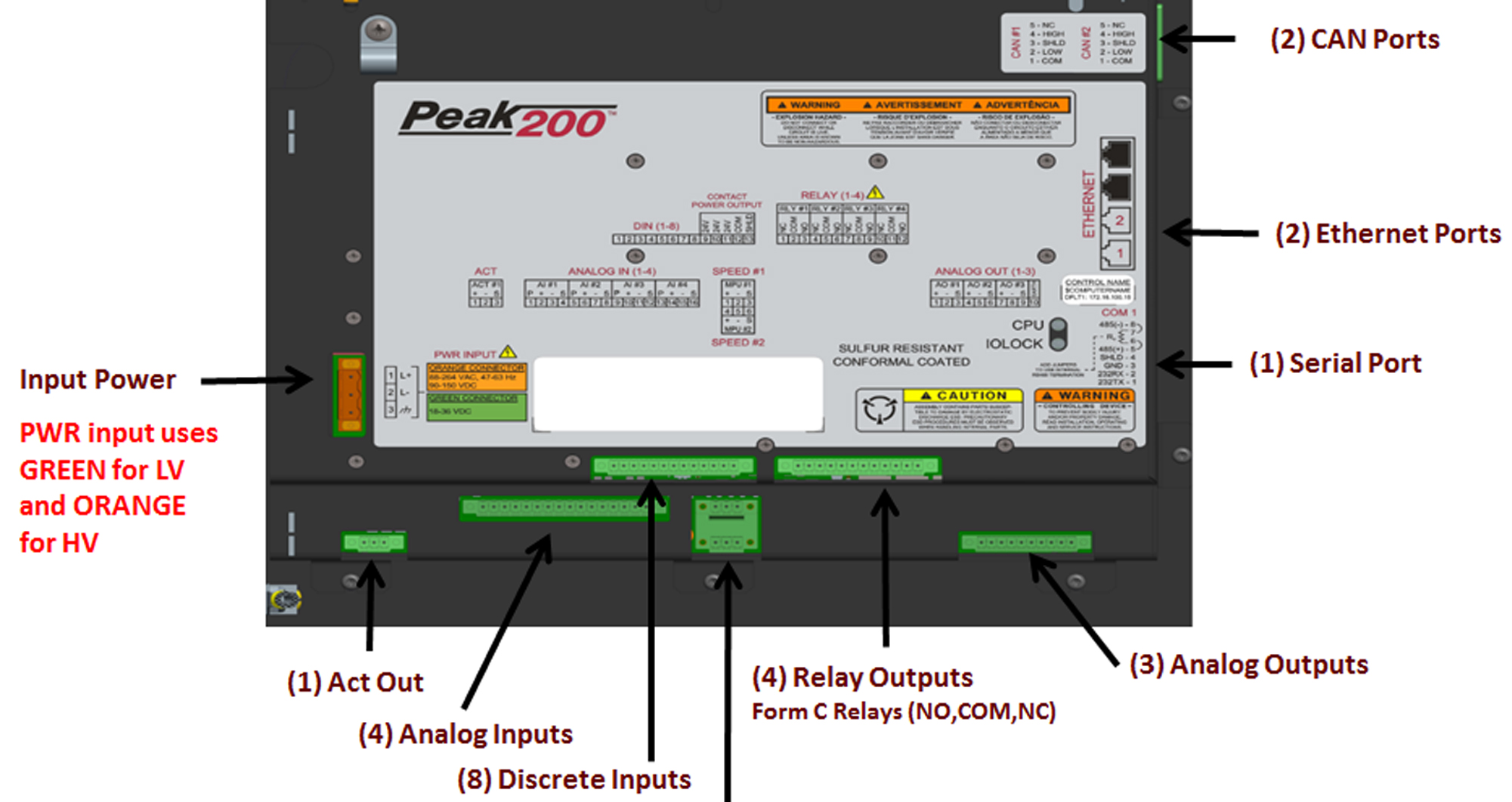

All models include:

Product Manual (English & Portuguese), Service Tool Kit (Computer based software programs), Remotely Configure & Service. Upload/download configuration settings. Monitor saved start and trip trends.

Power Supply Options

Location / Certification Options

Mounting Options

Auxiliaries

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Estamos disponible para servirle

Instalaciones de servicio completo en el Sureste; Costa Noroeste, y El Golfo. Además una red de agentes en

América Latina y el Caribe.

Please complete the form below. Non-Emergency Requests Only.

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!